Cured-in-place pipe, or CIPP for short, is a type of pipe repair technique that is becoming increasingly popular in the plumbing and construction industry. This sophisticated process involves the use of a specialized, flexible tube that is coated with a resin material, which is then inserted into the damaged pipe. Once in place, the tube is inflated, causing it to expand and harden, effectively creating a brand new, seamless pipe within the existing damaged pipe. The resulting cure is virtually leak-proof, as it provides a barrier that is highly resistant to root intrusion and other types of damage. As a result, CIPP has quickly become one of the most reliable, cost-effective solutions for rehabilitative plumbing and pipeline work in the industry.

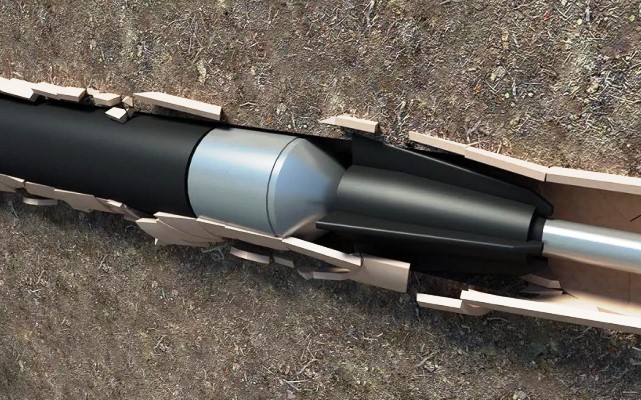

Pipe bursting is a highly effective method employed when the existing pipeline is in a state of severe damage that is beyond repair by regular pipe lining practices. The technique involves the use of highly advanced machines that are designed to pull a brand new pipe through the old one. The innovative procedure also features the fracturing of the old pipeline to aid in the installation of the new one. The reliable and efficient procedure is executed using a state-of-the-art cone-shaped bursting head, which is firmly attached to a robust steel cable. The bursting head is initiated to break or split up the older pipeline, and in the process, it pushes it into the surrounding soil making ample space for seamless and swift installation of the new pipe.

Contact us online or call us at (204) 817-2795 to schedule an appointment. We'll call you to confirm your time and send you a confirmation email with a picture of your plumber, so you know who's coming to your door.

We'll come to your home and find out where the leak is so we know the best way to fix it. Regardless of where the leak is, we will provide you with the most economical option to fix the problem, as well as direct pricing.

After we discover the location and cause of the leak, we will send you a follow-up survey asking how we handled the job. Not satisfied with our service? Let us know and we'll make it right.

Our sewer lines may not always be in our direct line of sight, but their functionality is crucial to our daily lives. These underground pipelines efficiently and seamlessly carry away wastewater from our properties. However, when they fail, it can result in messy, disruptive, and expensive repairs. Thanks to innovations in plumbing technology, Excel Plumbers in Winnipeg now offer a less invasive solution: Trenchless Sewer Line Repair.

Traditional sewer line repair often involves the backbreaking task of digging trenches to locate the faulty pipes. In contrast, the “No-Dig” Trenchless Sewer Line Repair process simplifies this operation to a significant extent. Excel Plumbers uses state-of-the-art technology that eliminates the need for extensive excavation, saving time, money, and preserving the aesthetics of your property.

The process involves creating two small access points at the beginning and end of the damaged pipeline. A high-quality, flexible tube coated with resin is then inserted and pulled through the existing line. This resin tube hardens to form a new pipe within the old pipe, essentially creating a pipe-within-a-pipe system. This approach is highly efficient, minimally invasive, and can be used to repair sewer lines made from different materials including cast iron, PVC, and clay.

Excel Plumbers’ Trenchless Sewer Line Repair service in Winnipeg is adept at resolving various sewer line issues. These include:

Corrosion: Older pipes made from iron and steel often corrode over time. This corrosion can lead to leaks and subsequent line failures. Trenchless repair can effectively address this issue by creating a new, corrosion-resistant pipe within the existing one.

Root Infiltration: Tree roots can invade sewer lines, causing severe blockages and eventual pipe failure. With trenchless repair, the root-damaged pipeline can be repaired without removing the tree or extensively digging up your yard.

Pipe Breaks and Cracks: Wear and tear, ground movement, or severe weather conditions can lead to broken or cracked sewer pipes. Trenchless repair can mend these damages efficiently, avoiding the need for complete replacement.

Choosing Excel Plumbers’ trenchless sewer line repair services in Winnipeg comes with several benefits:

Minimal Disruption: The trenchless repair method saves you from the mess and disruption of traditional digging methods. Your landscaping, driveway, and yard remain virtually untouched.

Cost-Effective: By eliminating the need for extensive excavation, trenchless repair often proves to be a cost-effective solution. You save on the costs associated with restorative work post repair.

Durability: The new pipe installed is resistant to corrosion, root intrusion, and has a lifespan of several decades, making this an incredibly durable solution.

Time-saving: Trenchless repair is quicker than traditional methods, meaning less downtime for your property’s plumbing system.

If you find yourself in need of sewer line repair, it’s worth considering Excel Plumbers’ trenchless sewer line repair services in Winnipeg. It’s a testament to the power of modern technology – a solution that preserves your landscape, saves time and money, and offers a reliable, long-term fix for your sewer line issues.

Both pipe lining and pipe bursting are trenchless methods of repairing or replacing damaged sewer lines, but they work in fundamentally different ways and are best suited to different kinds of problems. Here’s an overview of both methods and how they differ.

Also known as Cured-In-Place Pipe (CIPP) lining, this method involves creating a new pipeline within the existing damaged one. A flexible tube coated with a special resin is inserted into the damaged pipe and then inflated. As the resin hardens, it forms a new pipe inside the old one that is resistant to leaks and root intrusion.

This method is typically used for repairing leaks and minor cracks in the pipe, and it’s often preferred when the goal is to preserve as much of the existing pipeline as possible.

Pipe bursting, on the other hand, is a method used to completely replace a damaged pipe. A cone-shaped bursting head is inserted into the existing pipe and moved through it. As the bursting head moves, it breaks apart the old pipe (hence the term “pipe bursting”) and simultaneously pulls a new pipe into place behind it.

Pipe bursting is typically used when the existing pipe is too damaged for a liner to be effective, or if there are substantial blockages like tree roots that can’t be removed by other methods. It’s also the preferred method when the old pipe is made from materials like Orangeburg or clay that deteriorate over time, as it allows for a full replacement with a more durable material.

In summary, the key difference between the two methods is that pipe lining repairs and reinforces an existing pipe by creating a “pipe within a pipe,” while pipe bursting replaces the old pipe with a completely new one. The choice between the two will depend on the condition of the existing pipes and the specific needs of the repair situation.

💧 Experiencing a plumbing issue? Looking to upgrade your home’s plumbing system? In either case, you’re in the right place! We are Winnipeg’s leading provider of residential plumbing services, providing solutions that are both reliable and cost-effective.